APPLICATIONS

- Hydropneumatic systems

- Booster systems

- Irrigation systems

- Reduction of water hammer effects.

FACT SHEET

| Model: | MNP |

|---|---|

| Type: | Steel Tanks with Diafragm |

FEATURES

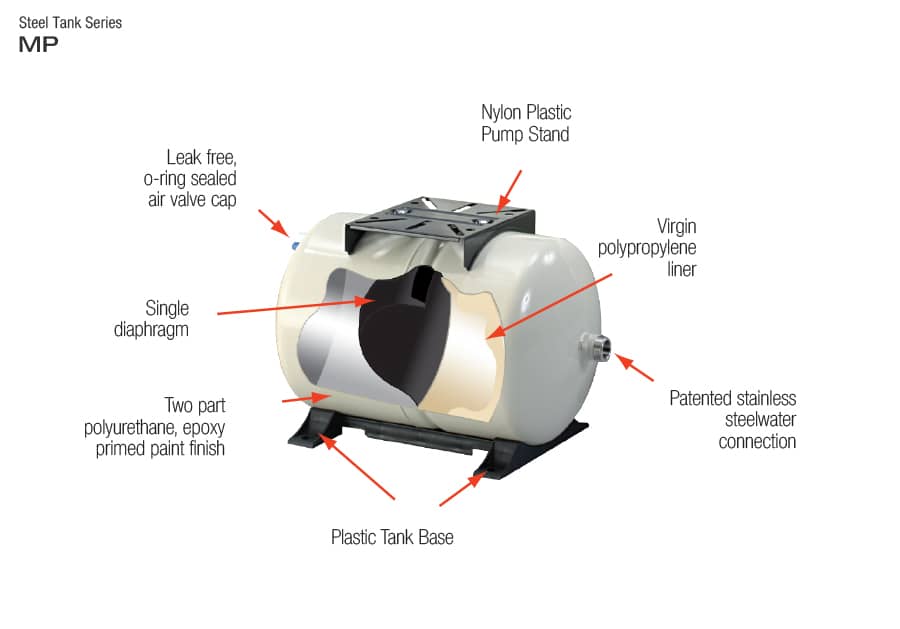

- Fixed Butyl membrane.

- Stainless steel water connection.

- Internal lining in virgin polypropylene.

- Finished with polyurethane paint on epoxy base.

- Air valve plug sealed with O-ring anti leak.

- No maintenance required.

- Maximum Working Pressure: 150 PSI / 10 bar.

- Maximum working temperature of water: 90 ° C.

- IAPMO R&T, ACS, CE certifications.

- Factory preload in Nitrogen (N2) for its operation.

- 100% Factory Tested.

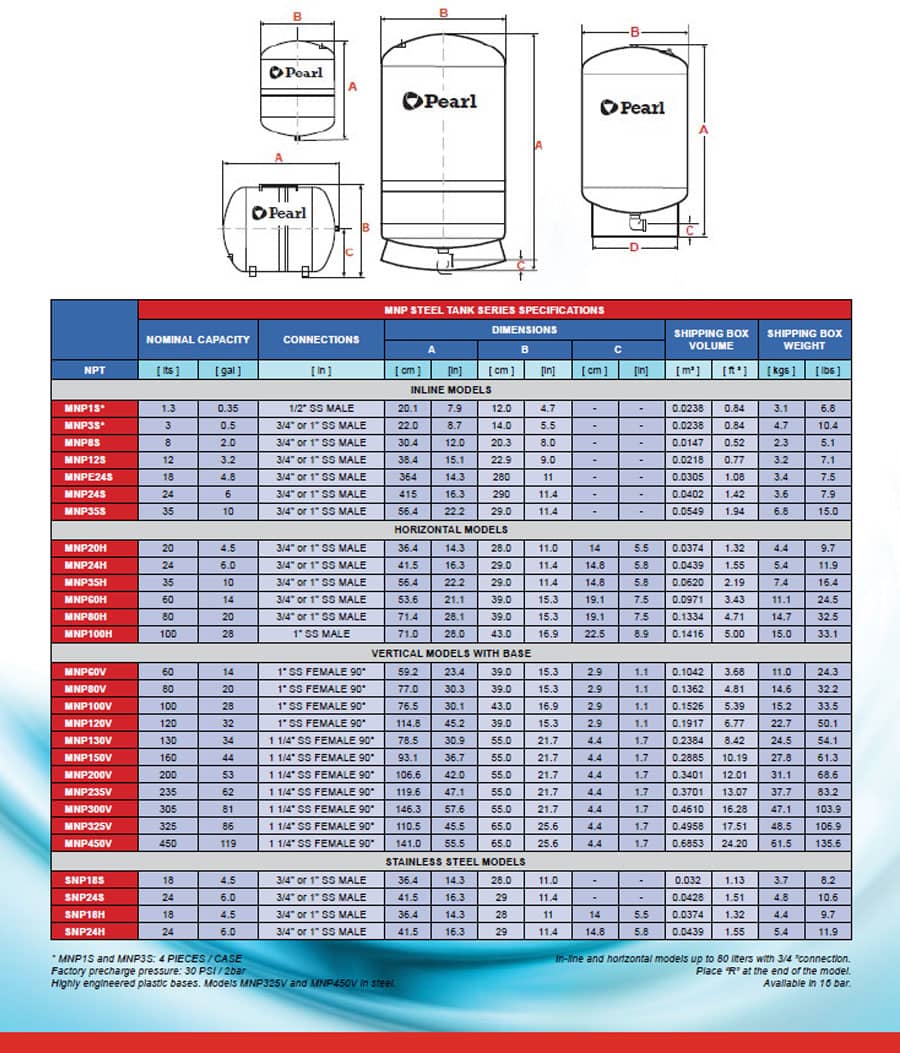

TECHNICAL DATA

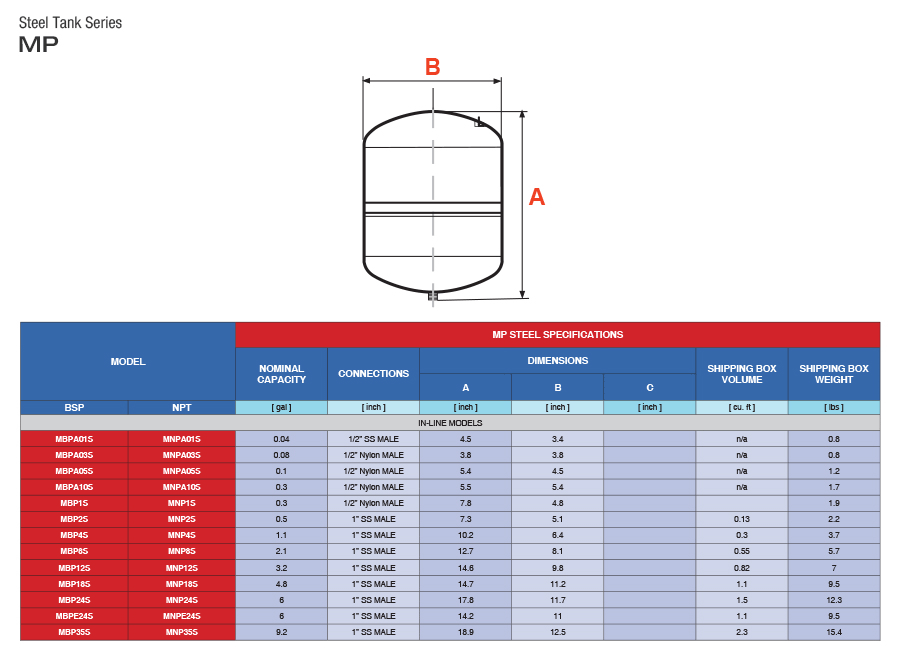

INLINE MODELS

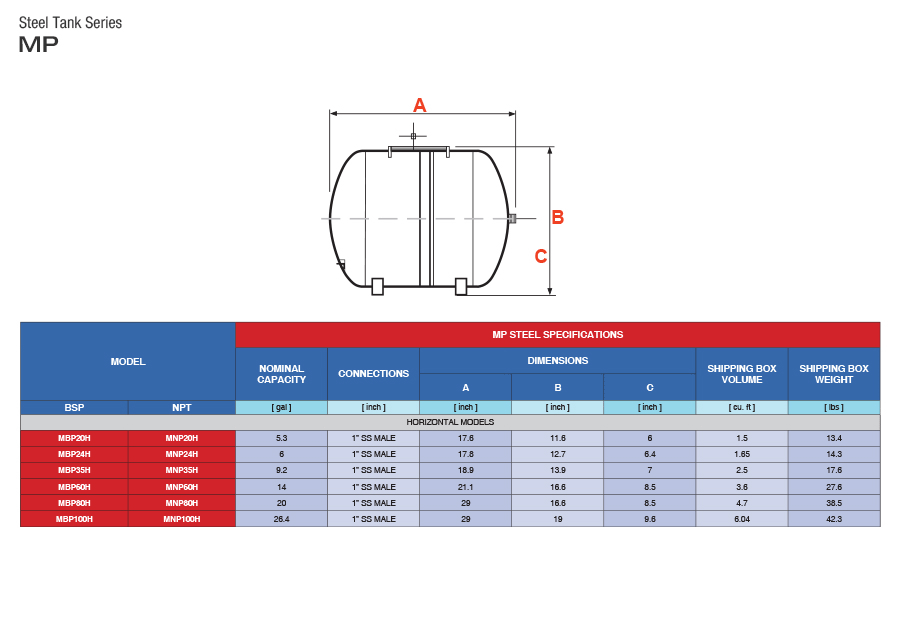

HORIZONTAL MODELS

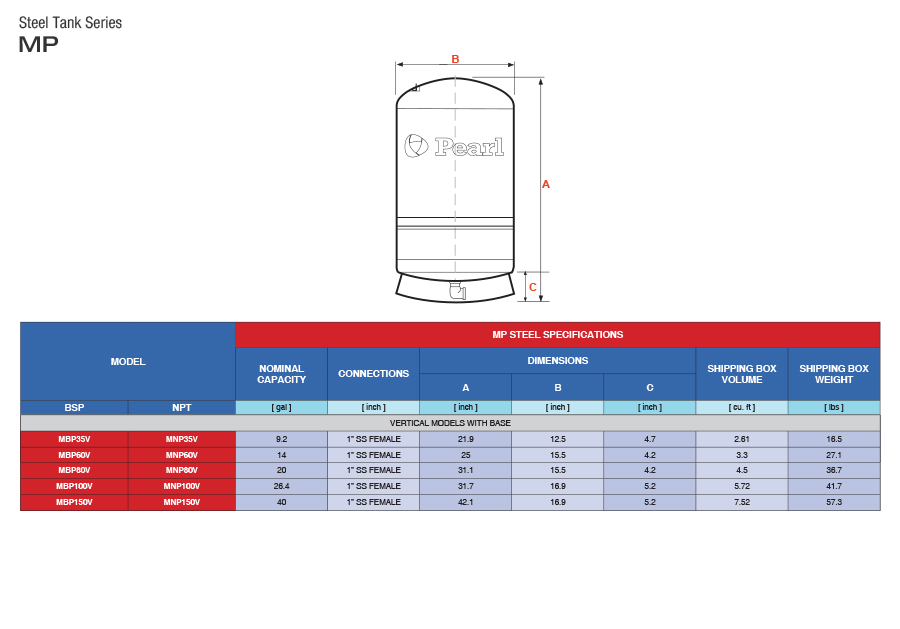

VERTICAL MODELS WITH BASE

STAINLESS STEEL MODELS

Features

MNP Features

Dimensions Vertical Tanks

MNP Dimensions Vertical Tanks

Dimensions Horizontal Tanks

MNP Dimensions Horizontal Tanks

Dimensions in Line Tanks

MNP Dimensions in Line Tanks

Nominal Current